1、 Scope of application:

Mechanical vapor recompression (MVR) evaporator is suitable for low-temperature concentration in industries such as milk, glucose, starch, monosodium glutamate, xylose, pharmaceuticals, chemical engineering, biotechnology, environmental engineering, waste liquid recovery, papermaking, and salt production.

2、 Equipment composition:

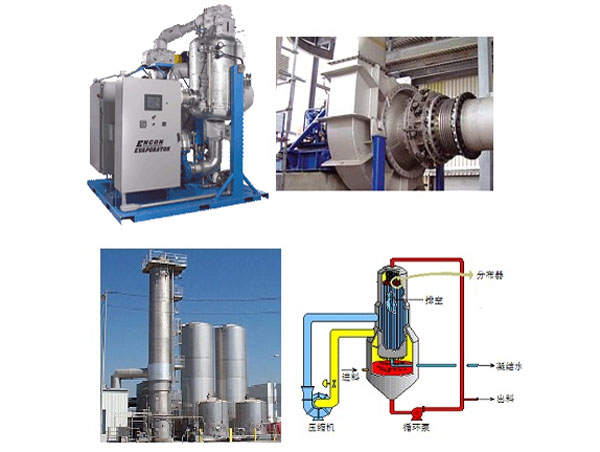

It consists of a single or triple effect evaporator, separator, compressor, vacuum pump, circulation pump, operating platform, electrical instrument control cabinet, valves, pipelines and other systems, with a very simple structure.

3、 Working principle:

Mechanical vapor recompression (MVR) evaporator utilizes the secondary steam generated in the evaporator, which is compressed by a compressor to increase pressure, temperature, and enthalpy. It is then sent to the heating chamber of the evaporator as heating steam, maintaining the boiling state of the feed liquid, while the heating steam itself condenses into water. In this way, the steam that was originally intended to be discarded is fully utilized, latent heat is recovered, and thermal efficiency is improved. The economy of steam production is equivalent to 30 effects of multi effect evaporation, reducing the demand for external heating and cooling resources, energy consumption, and pollution.

4、 Main features:

MVR energy-saving evaporator technology is currently the most advanced evaporator technology internationally, requiring only a very small amount of steam, greatly reducing the operating costs of enterprises and minimizing environmental pollution.

2. Due to the use of a compressor as a heat source, compared to traditional evaporators, the temperature difference is much smaller, which can achieve mild evaporation, greatly improving product quality and reducing scaling.

3. No need for condenser, simple structure and process, fully automatic operation, continuous operation, safe and reliable.

4. The equipment is equipped with CIP cleaning pipelines, which can achieve on-site cleaning. The entire equipment is easy to operate and has no dead corners.

5. The evaporator is used to evaporate materials under the condition of low temperature and no foam. The feed liquid is uniform, without material loss and coking.

5、 Technical parameters:

1. Product evaporation capacity: 5L/h-60t/h

2. Evaporation temperature: 40 ℃ -100 ℃

3. Power consumption per ton of water for evaporation: 25KW-100KW

4. Fresh steam consumption: 0t/h

5. Solid content of feed: No requirement

6. Solid content of discharge: can be directly evaporated to crystallization

7. Evaporation modes include: falling film, rising film, forced circulation, fluidized bed evaporation, countercurrent, stirring, spiral tube, etc

8. Heat exchange components: can be designed as plate, tube or other evaporators

Customer service1

Customer service1