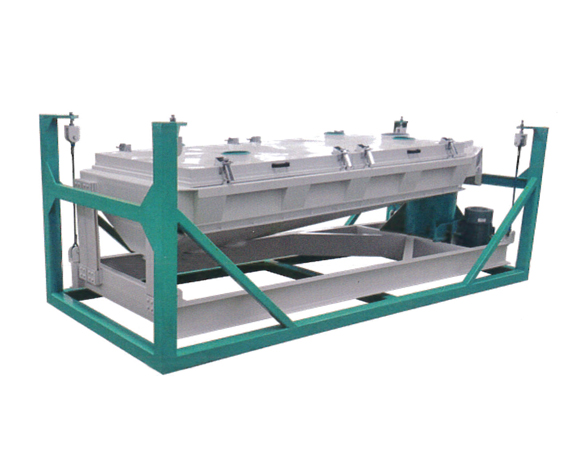

The working principle of a rotary screen is mainly based on the rotational motion of the screen body and the vibration of the screen surface. After the screening machine is started, the screening body (or screening box) begins to rotate under the action of the driving device. This rotational motion causes the material on the screen surface to be subjected to centrifugal force, resulting in distribution and grading along the screen surface.

Specifically, during the rotation of the screen body, the material is subjected to the vibration of the screen surface, causing the particles in the material to jump and roll on the screen surface. This movement helps to separate particles in the material through the sieve holes. Smaller particles can smoothly pass through the sieve holes and fall to the lower layer due to gravity and vibration of the sieve surface, becoming undersized material; However, larger particles, due to their larger size, cannot pass through the sieve holes and continue to remain on the sieve surface, moving towards the discharge port with the rotation of the sieve body.

During the operation of the rotary screen, the vibration of the screen surface and the rotation of the screen body work in synergy. The vibration of the screen surface helps to roll and jump the material particles, improving the screening efficiency; The rotation of the sieve body enables the material to be evenly distributed on the sieve surface and continuously screened along the sieve surface.

In addition, some rotary screens are equipped with auxiliary devices such as elastic balls to strike the sieve mesh, prevent material from blocking the sieve holes, and further ensure screening efficiency.

In general, the rotary screen achieves continuous screening and grading of materials through the rotation of the screen body and the vibration of the screen surface. This screening method has the characteristics of high efficiency and stability, and is suitable for screening and grading operations of various solid materials.

Customer service1

Customer service1