The SZG double cone vacuum dryer is a first generation drying device developed by our factory in combination with similar domestic product technologies, SZG double cone vacuum has a two-stage elastic connection method of belt and chain, so the equipment runs smoothly. The specially designed tooling fully embodies the good concentricity of the two shafts, and the heat medium and vacuum system use reliable American technology rotary joints. On this basis, we have developed SZG-A, which can achieve both stepless speed regulation and constant temperature control. As a professional drying equipment manufacturer, we serve our customers with over a hundred units per year. Our products range from high-temperature heat transfer oil as the heat medium, medium temperature steam, and low-temperature hot water. When drying viscous materials, our factory will specially design a container for you; Copy the board; Institution or installation of ball bearings.

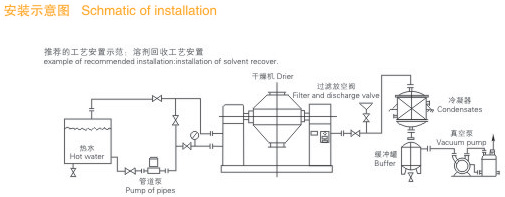

Principle: Heat energy (such as hot water, low pressure, steam, or thermal oil) is introduced into a sealed interlayer, and the heat is transferred to the dried material through the inner shell.

Under the power drive, the tank rotates slowly, and the materials inside the tank continuously mix, thereby achieving the purpose of strengthening drying.

The material is in a vacuum state, and the decrease in vapor pressure causes the water (solvent) on the surface of the material to reach saturation and evaporate, which is promptly discharged and recovered by a vacuum pump. The moisture (solvent) inside the material continuously permeates, evaporates, and is discharged to the surface, and these three processes are carried out continuously, achieving the drying purpose of the material in a very short time.

characteristic:

When oil is heated, automatic constant temperature control is used to dry biochemical products and mineral raw materials, and the temperature can be between 20 and 160 ℃.

High thermal efficiency, more than twice as high as a typical oven.

Indirect heating ensures that the material is not contaminated and meets the requirements of GMP. The equipment maintenance operation is simple and easy to clean.

Application:

Suitable for the concentration, mixing, drying of powdered, granular, and fibrous materials in industries such as chemical, pharmaceutical, and food, as well as materials that require low-temperature drying (such as biochemical products). It is also more suitable for drying materials that are prone to oxidation, volatility, heat sensitivity, strong irritation, toxicity, and materials that do not allow crystal destruction.

技术参数表:

|

规格 名称 | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| 罐内容积 | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| 装料容积 (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| 加热面积 (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

| 转速 (rpm) | 4 - 6 | |||||||||

| 电机功率 (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

| 占地面积长×宽(mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

| 回转高度(mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

罐内设计压 (MPa) | -0.1-0.15 | |||||||||

| 夹套设计压力 (MPa) | ≤0.3 | |||||||||

| 工作温度 (oC) | 罐内≤85 夹套≤140 | |||||||||

| 用冷凝器时,真空泵, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| 型号,功率 | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

| 不用冷凝器时,真空泵 , | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| 型号,功率 | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| 重量(kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

注:对干燥前后容积变化很大的物料,其装料系数可适当加大或缩小。

Customer service1

Customer service1